Glassfibre Hulls

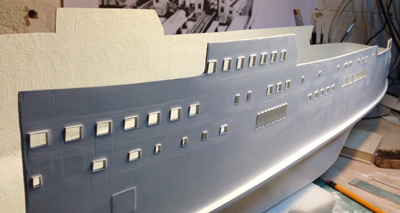

Your Linkspan Models hull is made from layers of woven glass mat embedded in epoxy resin. The outside surface is a gelcoat - the first coat that was laid into the mould. The gelcoat is an epoxy layer designed to give a smooth finish that hides the texture of the mat within.

Be particularly careful when working on the hull, as gelcoats are prone to chipping. Your hull will require cleaning with a little detergent to remove any release waxes from the moulding process.

Before being internally braced with wood, all glassfibre hulls are at risk of deforming. Check your hull matches the dimensions detailed on the plans. If any deformation has occurred, it is recommended to use a hairdryer to bring it back to shape.

You will need to drill into the glassfibre hull during construction. To avoid damage to the gelcoat you should cover the area to be drilled with masking tape. Proceed slowly. For larger open areas in the hull you can either drill a series of holes along an edge, or use a cutting disk on a suitable hobby tool.

Finish off these edges with a file - but make sure your file's cutting strokes go from outside to inside.